My team modeled and manufactured via a direct metal laser sintering (DLSM) process a propellant management device (PMD), which is a critical component that makes up spacecraft propellant tanks.

PMD function to transport gas free fuel to the engine of the rocket in low-gravity environments. Without a way to ensure liquid and gas are separated, engine failures will occur mid flight.

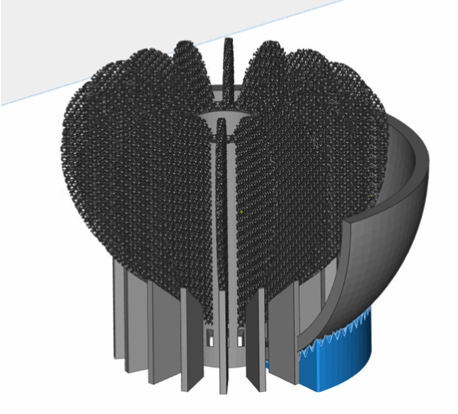

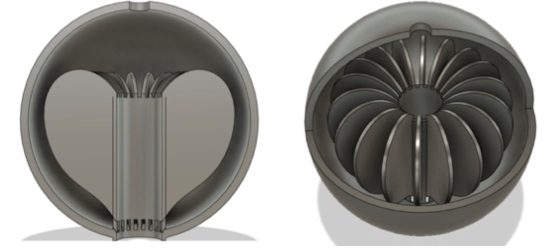

The motivation behind 3D printing a PMD is that by incorporating lattice structures into current sponge designs the efficiency of the PMD will improve.

I helped create CAD renderings of the sponge PMD in Solidworks. I then exported the CAD file to the EOS 3D printing client.

Here, I added structural and thermal supports to the PMD to prevent warping during the build process. All supports can be removed using EDM and ones that couldn’t be cut can be machined off. Powder removal is a critical issue especially in our design.

Leave a comment